The basic manufacturing process of our rudders has remained unchanged for over 40 years. This time-proven process has yielded strong, reliable and long-lasting rudders.

back to: Main Rudder Page

Through the years we have adapted new materials in order to improve strength, durability, and reliability. The closed cell foam core of the rudder remains the same, but the selective addition of unidirectional fibers has increased the strength of our rudders, and the use of Vinylester™ resins has eliminated blisters and the need for expensive barrier coats.

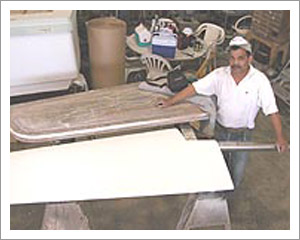

Here is a closer look at how we manufacture our rudders: